A New Chemical Design for The Surface of Biomaterials

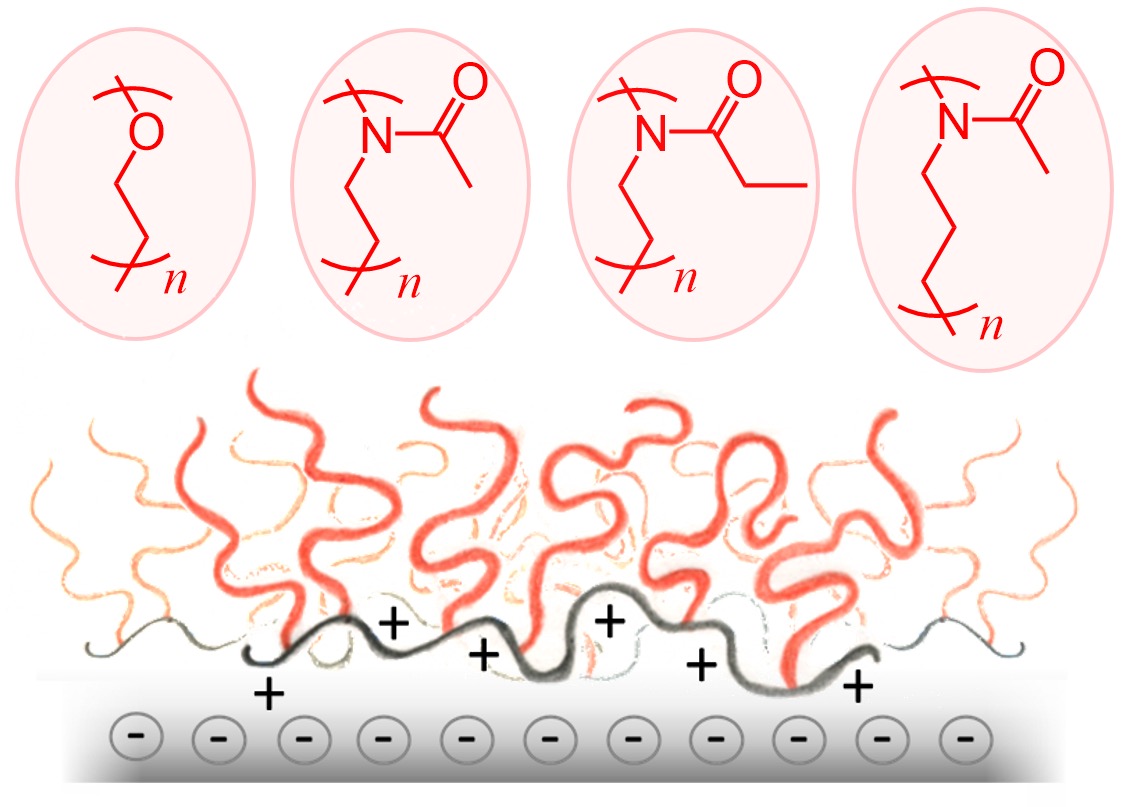

A research team led by Dr. Edmondo M. Benetti (Polymer Surfaces Group) and Prof. Richard Hoogenboom (Ghent University) carried out a comprehensive, comparative analysis of the structural and physicochemical properties by non-ionic polymer “brush” surfaces that are aiming to replace poly(ethylene glycol) (PEG) in the functionalization of exposed surface of biomaterials.

The intrinsic drawbacks associated with the application of poly(ethylene glycol) (PEG) in the functionalization of the exposed surface of biomaterials are nowadays becoming evident. These include its poor chemical stability under physiological environments, the formation of toxic side-products from polymer degradation, and the increasing cases of immunoresponse towards its derivatives. A research team led by Dr. Edmondo M. Benetti (Polymer Surfaces Group, DMATL) and Prof. Richard Hoogenboom (external page Ghent University) carried out a comprehensive, comparative analysis of the structural and physicochemical properties by non-ionic polymer “brush” surfaces that are aiming to replace PEG in the designing of biointerfaces.

The groups of Benetti and Hoogenboom especially focused on poly(2-alkyl-2-oxazoline)s (PAOXAs), emerging polymers in biotechnology, and poly(2-methyl-2-oxazine) (PMOZI), a polymer that is isomeric to, but structurally different from poly(2-ethyl-2-oxazoline) (PEOXA). In the exemplary case of the functionalization of metal oxide-based medical devices, the biopassive properties of PEG, PAOXA and PMOZI brushes towards non-specific protein adsorption and cell adhesion were tested. In addition, the capability of the different brushes to generate a lubricious film that mimics the tribological properties of natural biolubricants was investigated. The results originating from a combination of surface-sensitive techniques and atomic force microscopy (AFM) methods highlighted that PAOXA brushes can form biopassive and lubricious films matching, and in some cases surpassing the attractive properties of PEG analogues. The presence of an additional methylene group within the polymer repeating unit, as in the case of PMOZI brushes, maintains their hydration capabilities unaltered in comparison to the most hydrophilic poly(2-methyl-2-oxazoline) (PMOXA), while it increases main-chain flexibility. The combination of high hydration and enhanced chain flexibility generates an exceptional enthalpic and entropic barrier against protein and cell adhesion, and provides extremely low friction to the functionalized surfaces.

Hence, PMOZI emerges as a new polymer for the generation of brushes with unprecedented properties, significantly surpassing the state-of-the-art, and opening up a variety of applications in the modification of tissue-engineering constructs, the designing of biosensors and cell-sensitive platforms. While providing a general comparison among some of the most promising candidates for the replacement of PEGs in the fabrication of biointerfaces, these data re-define the combination of the structural and physicochemical parameters that must be taken into account in order to fabricate a fully bioinert and functional polymer coating for biomaterials.

You can read more about the properties of non-ionic polymer brush surfaces in Angewandte Chemie International Edition: