Martin Elsener: Working as a Materials Inspector at the Winter Olympics in Pyeongchang

A look behind the scenes: A working day as material inspector of the International Bobsleigh and Skeleton Federation (IBSF) at the Winter Olympics in Pyeongchang.

By Martin Elsener

After four years of studying bobsled and skeleton construction during the Citius project here at the ETH, the Vice President for Sport of the International Bobsleigh and Skeleton Federation (IBSF) asked me if I would like to apply as a materials inspector at the IBSF. I did this, and now I find myself working as a materials inspector at the Winter Olympics in Korea.

At 7:30 the materials inspectors team, Dragos Panaitescu (ROU), Hermann Gigacher (AUT) and I met for breakfast, after which we went immediately to the bobsled run, up to the launch area, to be present at training. There we mostly provided information on technical aspects, details of the timing of runner controls and the like. The mere presence of materials inspectors indicate clearly that everything is carried out according to the regulations.

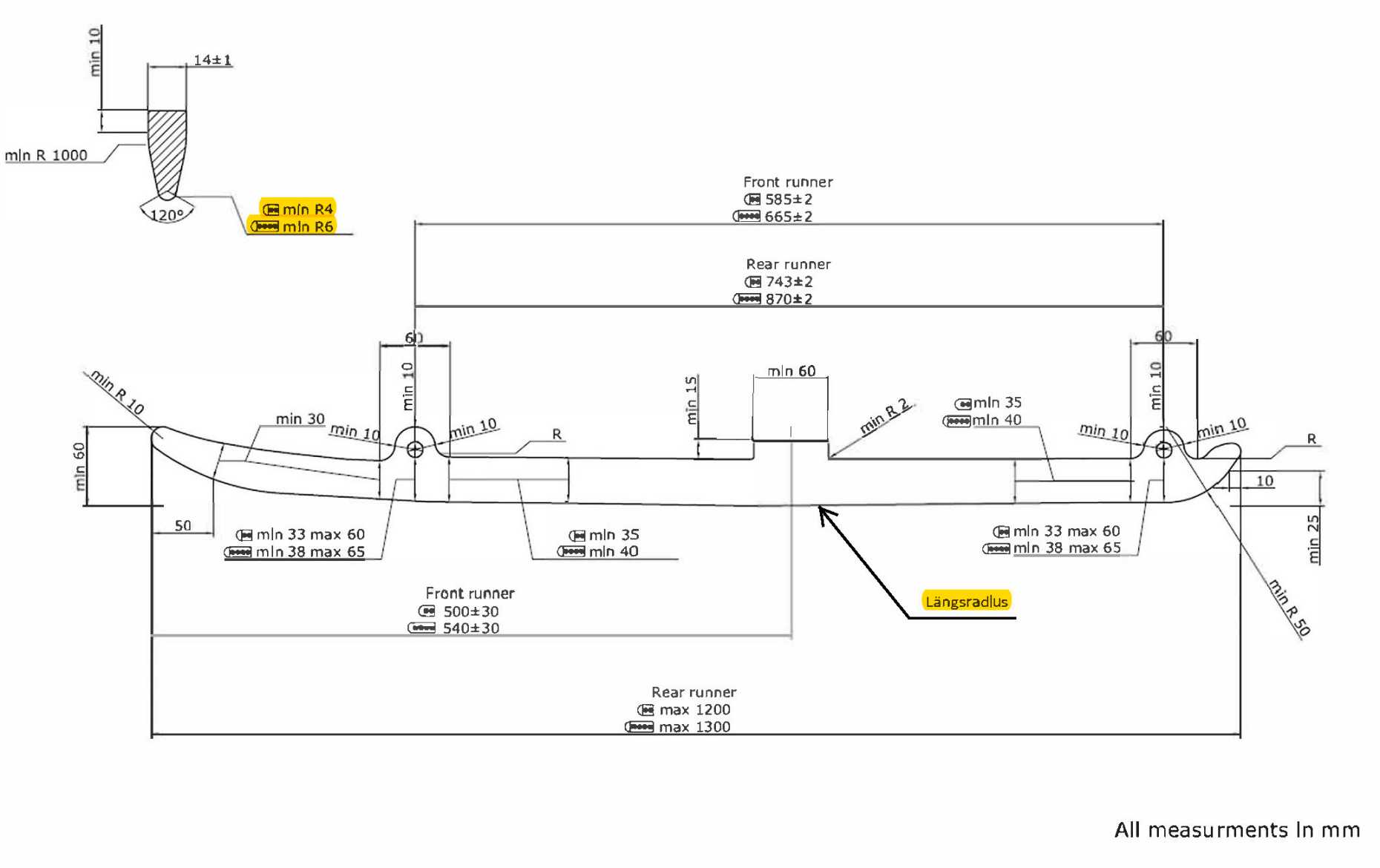

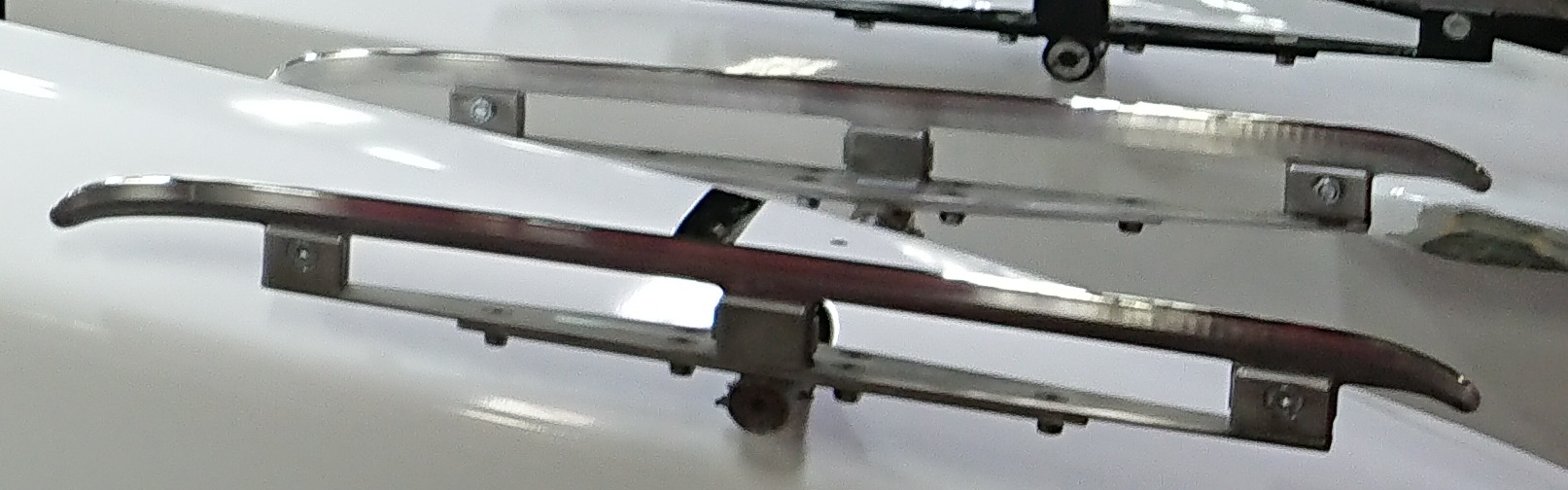

For example, the only runners which may be deployed are those certified by the official IBSF materials inspectors. The respective tests look at geometrical form and dimensions, the alloy of the runner material and its hardness. The alloying elements are checked using a handheld X-ray apparatus. Various measurements are taken within a few seconds for a reproducible result. Of course, all measurements are stored and may be referred to and further processed at a later date. If all measurements are within the regulations the runners get a vignette similar to a motorway toll vignette.

The runner inspection and approval filled the afternoon, and we were grateful for having enough time to pack up the material for the men’s two-man race and put it in the car. Then it was time to return to the launch area and get ready for the race. It was 18:15, which left us time for a snack before the race.

Before the race the bobsleds are set up in a designated area, the "parc". They are prepared in such a way that the runners can be attached as late as possible. Work on the bobsleds must be finished 45 minutes before the race begins. During the final 45 minutes, the "parc" is closed: "parc fermé". Only the jury, the materials inspectors and assigned helpers are allowed to stay. It is then that the first inspections of the race begin.

The first thing to check is whether all runners have a valid vignette. Then comes the runner radius. Several years ago people raced with as narrow a radius as possible; this has changed in the meantime. Bob handling is more sensitive with large radii but they are faster if the trajectory is right. Pressure and speed cause the ice under the runners to melt and the bobsled travels on a film of water. The smaller the radius, the greater the depth of penetration in the track and the associated navigatory precision. Larger radii work the other way. At the Department of Materials the Surface Science and Technology group has been conducting intensive research for a year regarding friction on ice during bobsledding. They have gained knowledge which would generate even more speed if implemented, but which is quite difficult to achieve in practice. In the Department of Mechanical and Process Engineering, research and calculations were carried out on the runner shape, especially the longitudinal radius. Interestingly, it turned out that runner shapes, which in theory can lead to faster gliding, in practice retard speed by several seconds. For this reason researchers have stuck to the classical shape and have concentrated on optimising it according to the track profile.

In the "parc fermé", the runners are wiped with a cloth soaked in orange acid. After a certain exposure time they are wiped with a cloth permeated with acetone. Both cloths are bagged, sealed and labelled with the start number. Then they are collected and stored by the jury. The handheld X-ray apparatus is then used again to check whether any coatings are present. A particular fluid is applied to check the surface tension and ascertain whether there is any forbidden material on the runner which was not recognised by the X-ray apparatus. The surface tension is the property of a fluid which appears at or near the surface via balanced molecular forces. If the associated energy is higher than the surface energy of a material the fluid tends to form droplets instead of spreading out. After the whole procedure the fluid is wiped off again.

Before the bobsleds are put into the starting lane, the runner temperature is measured. The temperature must be within a range specified by the regulations. If the temperature is too high, the jury can specify a certain time during which the bobsleds are placed on an offside bed of ice to cool down.

Following all of this technical activity the race can begin – and we materials inspectors can allow ourselves a cup of tea. Between the heats only material issued by the IBSF may be used. Sandpaper in an envelope and cleaning materials are given out and handed back after use. This work may only be carried out by the team members competing in the race. Repairs are carried out exclusively under the supervision of the jury.

As soon as all envelopes have been collected we materials inspectors return to the control container to prepare the bobsleds controls after the race. Under the supervision of a jury member, selected teams must bring us their sleds after the race for checking. The inspection includes checking the frame construction, material alloys and the dimension of the hull. The details of what happens in the container are confidential, and photography is forbidden.

In the meantime it is 00:15, and a long working day is coming to an end. But not quite – there is a little apéro in the hotel lobby, where we discuss the day. It is interesting to see how much time and money are invested in materials, just for that decisive fraction of a second. Still, what really makes a sled go fast remains a mystery even today. There are bobsleds which were built according to the same plan using exactly the same materials, but one is fast and the other is not. The future may bring us research, calculations and stabs in the dark, but no one really knows what the outcome will be.

Not every day was as full as this one. We also had time to visit the Olympic Park and to watch various events. The Games were fantastically organised, and there were always volunteers around. What also impressed me was the relaxed atmosphere among the athletes, despite the great emotions at reaching – or missing – the intended goal. People were very friendly and open towards us, even if we were sometimes reduced to nonverbal communication.

All in all, an experience that will remain unforgettable.