Ultrastable, Biopassive and Lubricious Coatings by Cyclic Polymers

A research team led by Giulia Morgese and Edmondo M. Benetti (Polymer Surfaces Group) has demonstrated that the application of cyclic poly(2-alkyl-2-oxazoline)s (PAOXA) at the interface of bilayer coatings generates polymer surfaces that can withstand very aggressive biological environments and simultaneously provide extremely low friction.

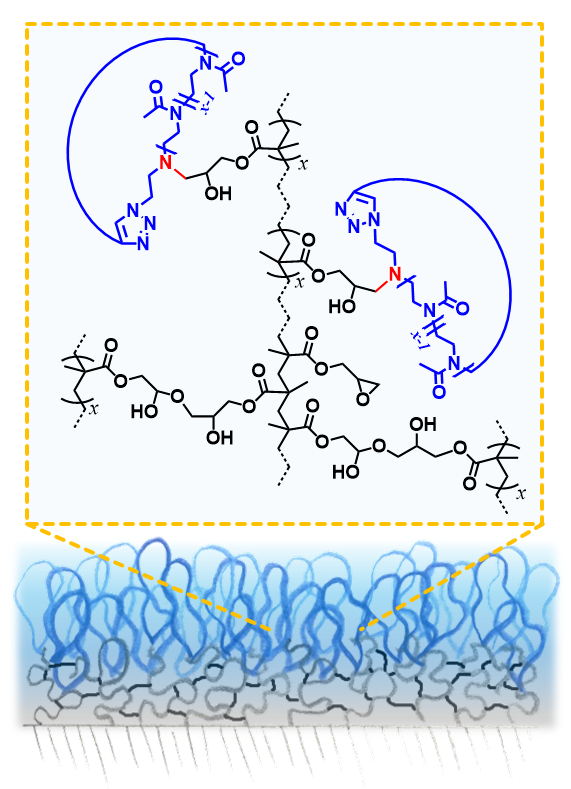

In particular, the unique topology effects by cyclic poly(2-methyl-2-oxazoline)s (PMOXAs) and poly(2-ethyl-2-oxazoline)s (PEOXAs) enable the fabrication of ultradense ring “brushes” on covalently crosslinked poly(glycidyl methacrylate) (PGMA) films. The combination of high polymer density, enhanced hydration and absence of chain-ends provided by cyclic PMOXA and PEOXA grafts quantitatively suppress non-specific interactions with biological media and provide lubricious properties to the polymer interface. These attractive traits are coupled to a remarkable structural stability of the entire coatings in aqueous environments featuring different compositions, ionic strengths and biological contents. Besides demonstrating the impact of polymer topology effects under the confinement of macroscopic surfaces, bilayer coatings based on cyclic PAOXAs emerge as very promising materials for the functionalization of technologically relevant inorganic platforms, such as implants, sensors or micromechanical devices that undergo shear stresses within aqueous media.

You can read more about the design of ultrastable, biopassive and lubricious cyclic PAOXA films in the current issue of Polymer Chemistry, which features the work of the researchers from DMATL in its front cover.

Design and characterization of ultrastable, biopassive and lubricious cyclic poly(2-alkyl-2-oxazoline) brushes, Wenqing Yan, Mohammad Divandari, Jan-Georg Rosenboom, Shivaprakash N. Ramakrishna, Lucca Trachsel, Nicholas D. Spencer, Giulia Morgese and Edmondo M. Benetti, Polym. Chem., 2018, 9, 2580-2589, external page DOI:10.1039/C7PY02137B

Polymer Surfaces Group