New viscoelastic materials that simultaneously combine high stiffness and high loss

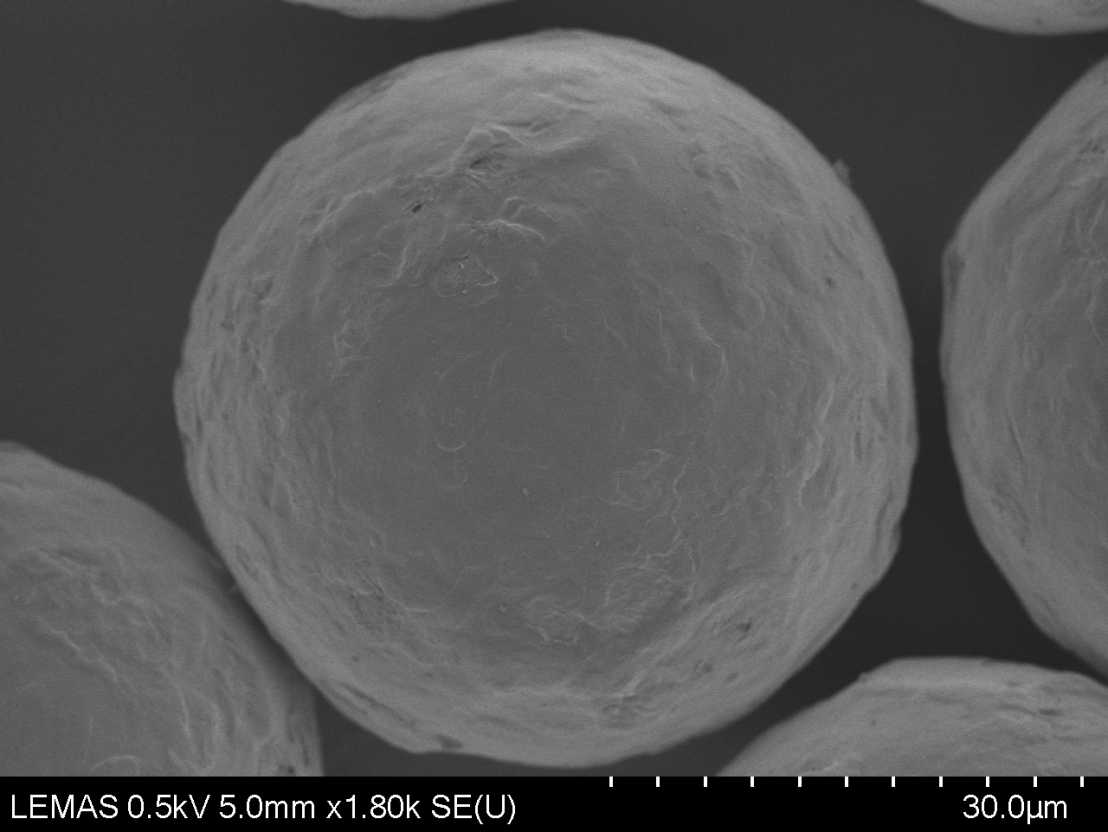

The stiffness modulus and loss tangent are usually mutually exclusive properties so it is a technological challenge to develop materials that simultaneously combine high stiffness and high loss. A team of researchers from UK, Japan and Switzerland led by Andrei Gusev (Polymer Physics) has achieved this unusual balance of properties by filling a solid polymer matrix with rigid inorganic spheres coated by a sub-micron layer of a viscoelastic material with a high level of internal friction.

The starting focus for the work was provided by the optimum material microstructure of rigid spheres coated with a sub-micron viscoelastic layer embedded in a solid polymer matrix, previously established in our finite element numerical simulations. It was demonstrated that this material combination can be experimentally realized and that the numerically predicted behavior is closely reproduced, thereby escaping the often termed ‘Ashby’ limit for mechanical stiffness/damping trade-off and offering a new industrial route for manufacturing advanced composite structures with markedly reduced noise and vibration levels.

- external page Gusev, A.A. Optimum microstructural design of coated sphere filled viscoelastic composites for structural noise and vibration damping applications. International Journal of Solids and Structures 128, 1–10 (2017)

- external page Unwin, A.P., Hine, P.J., Ward, I.M., Fujita, M., Tanaka, E., Gusev, A.A. Escaping the Ashby limit for mechanical damping/stiffness trade-off using a constrained high internal friction interfacial layer. Scientific Reports 8: 2454 (2018)

- external page Gusev, A.A., Hine, P.J., Unwin, A.P., Ward, I.M., Fujita, M., Tanaka. Inventors; Composite material and method for improving damping property thereof WO 2017/094266 A1 (PCT/JP2016/005042) Publication Date 8th June 2017