Catalyst-Free Depolymerization of Polymers Synthesized by Controlled Radical Polymerization

In a recent article, researchers from the Laboratory of Polymeric Materials were able to reverse reversible addition–fragmentation chain-transfer (RAFT) polymerization and regenerate the starting monomer which they can then use to either retrieve the initial polymer or produce a completely different material.

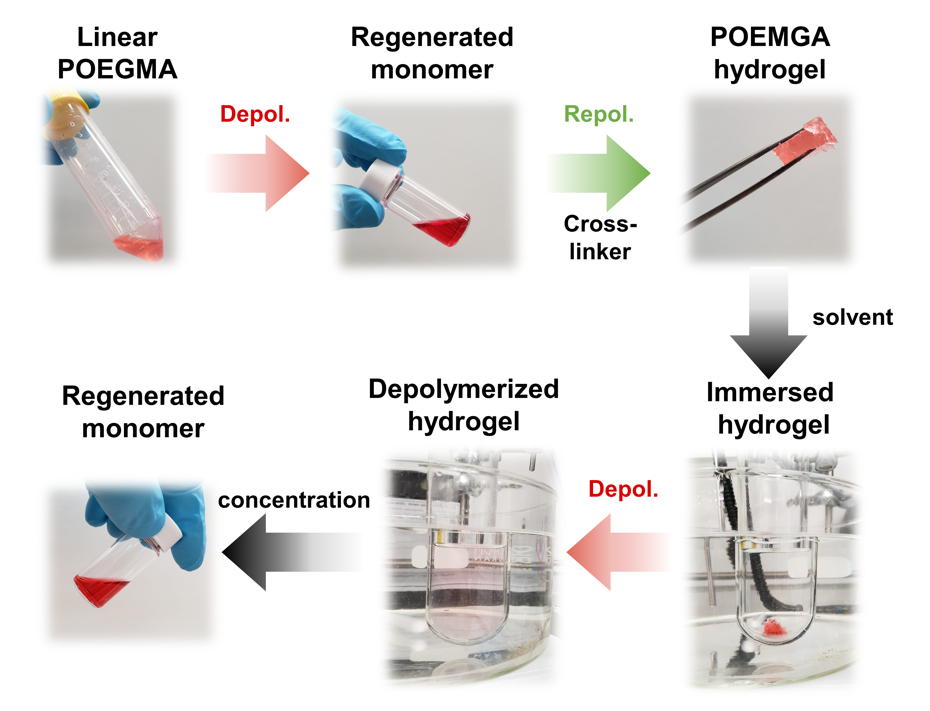

The ability to reverse controlled radical polymerization and regenerate the monomer would be highly beneficial for both fundamental research and applications, yet this has remained very challenging to achieve. In this work we report a near-quantitative (up to 92%) and catalyst-free depolymerization of various linear, bulky, cross-linked, and functional polymethacrylates made by reversible addition–fragmentation chain-transfer (RAFT) polymerization.

Key to our approach is to exploit the high end-group fidelity of RAFT polymers to generate chain-end radicals at 120 °C. These radicals trigger a rapid unzipping of both conventional (e.g., poly(methyl methacrylate)) and bulky (e.g., poly(oligo(ethylene glycol) methyl ether methacrylate)) polymers. Our colleagues from the Australian National University performed simple thermodynamic calculations to validate our data. Importantly, the depolymerization product can be utilized to either reconstruct the linear polymer or create an entirely new insoluble gel that can also be subjected to depolymerization. This work expands the potential of polymers made by controlled radical polymerization, pushes the boundaries of depolymerization, offers intriguing mechanistic aspects, and enables new applications.

The paper was published in J. Am. Chem. Soc. 2022, 144, 4678-4684. external page DOI:10.1021/jacs.2c00963

This work was highlighted by: