Tailoring Polymer Dispersity for any Material Class possible via Controlled Radical Polymerization

Researchers in the Laboratory of Polymeric Materials have developed a straightforward and versatile batch method to tailor the molecular weight distributions for any material that can be synthesized via controlled radical polymerization. The approach creates many opportunities to tune polymer dispersity in a diverse range of applications. The experimental findings of the group were supported by kinetic modelling conducted by a group at Monash University and the work was published in Chem.

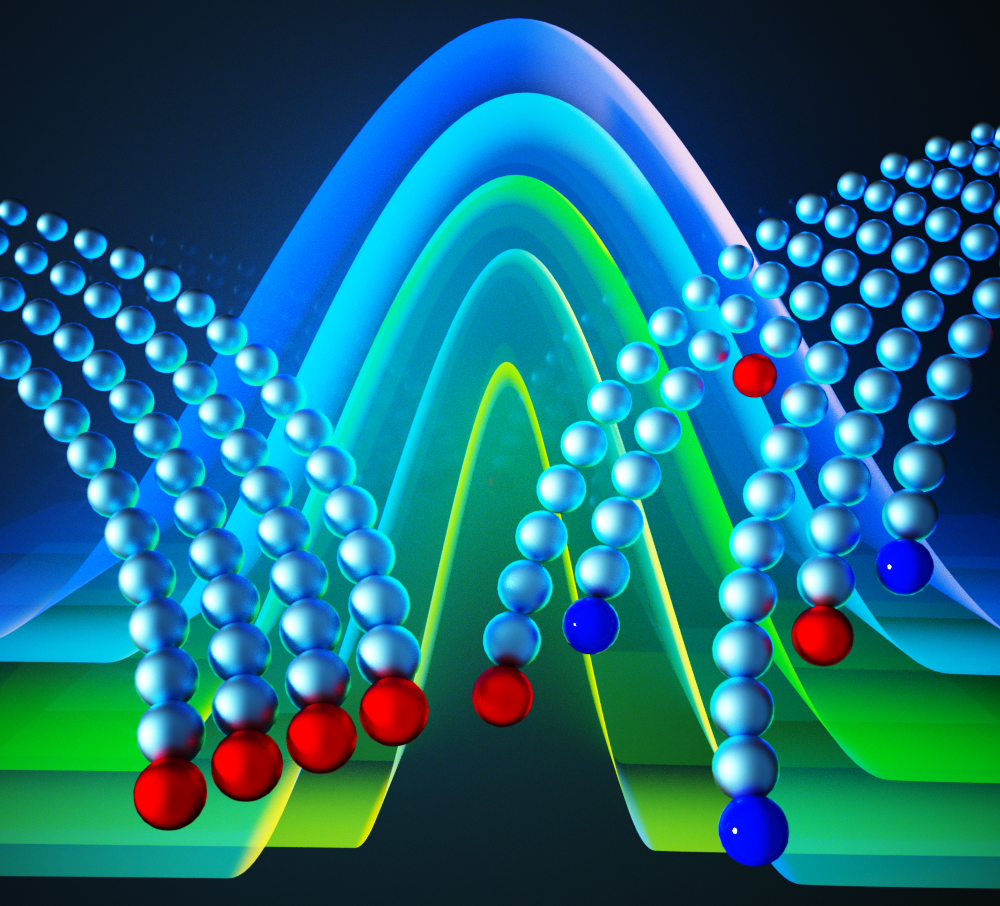

Unlike natural biopolymers, such as DNA and proteins, synthetic polymers have a distribution of different molecular weight species. This distribution is measured by a dispersity value and has a significant influence on polymer properties. It is therefore highly beneficial to develop strategies to systematically tune the dispersity, but to date current methods have limitations in monomer scope, block co-polymer accessibility, and attainable dispersity range. In this work, we describe a controlled radical polymerization (CRP) method, which enables good control over Ɖ for a range of polymer classes. By mixing two chain-transfer agents or catalysts of different activity in reversible addition-fragmentation chain transfer (RAFT) polymerization, homopolymers and block co-polymers with a wide dispersity range can be prepared. Our method addresses a common misconception in polymer chemistry where polymers of higher dispersity are associated with low livingness while providing access to a range of dispersity values for any polymeric material that can be synthesized by controlled radical polymerization.

Our work was published in the scientific journal Chem and has been further highlighted by Nature Chemistry Reviews, Chem and ETH news:

- highlighted by external page Nature Chemistry Reviews

- highlighted by external page Chem

- highlighted by ETH News

- Whitfield R, Parkatzidis K, Truong NP, Junkers T, Anastasaki A: Tailoring Polymer Dispersity by RAFT Polymerization: A Versatile Approach. Chem, Vol. 6, Issue 6, P 1340-1352, June 11th 2020. external page doi:10.1016/j.chempr.2020.04.020

- Laboratory of Polymeric Materials