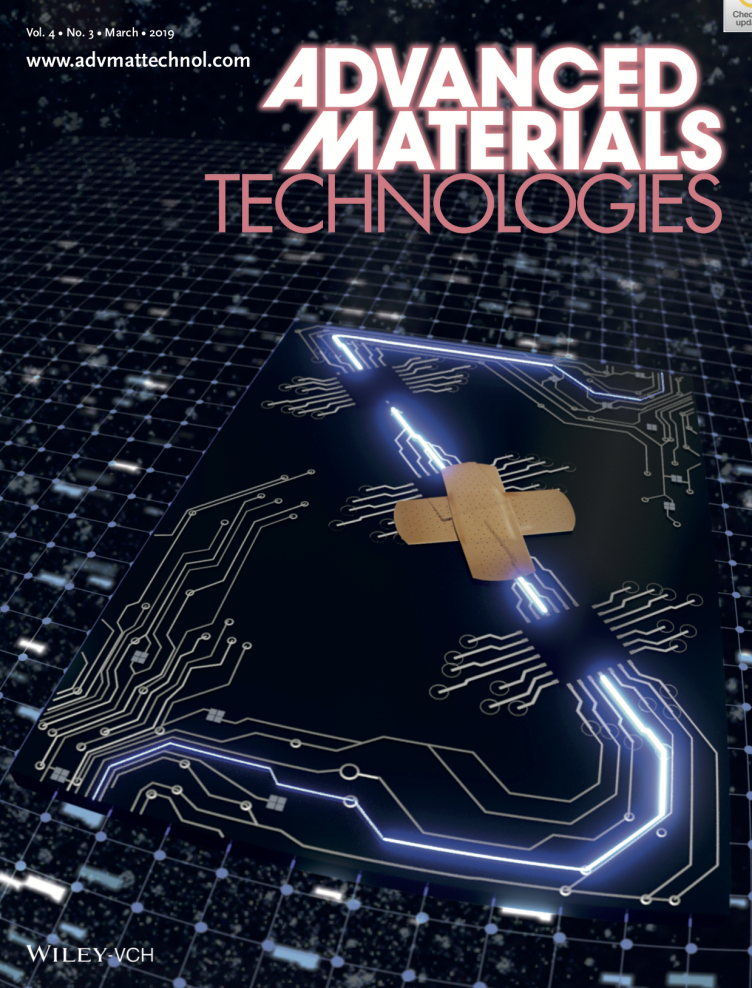

On-demand Healing of Metal Films: A First Step Towards Self-healing Electronics

Researchers from the Laboratory for Nanometallurgy at the Department of Materials at ETH Zürich have developed a novel technique for on-demand healing of metal thin films based on the use of an intrinsic heat source.This work represents a first step towards self-healing electronic.

In pursuit of creating materials that, like animals and plants, can heal themselves, many new and fascinating so-called “self-healing” materials have been developed. Self-healing or healable materials have the capability to repair structural damage, thus removing the need for parts exchange or manned repair operations and reducing the raw materials consumption to a minimum.

Researchers at the Department of Materials at ETH Zürich have extended the concept of healing to metals, developing a novel technique for on-demand healing of metal thin films based on the use of an intrinsic heat source that allows to restore the electrical properties of conducting films similar to those present in modern microelectronics. The healing process is extremely quick, efficient and can be activated at room temperature with simple power sources a watch battery. The concept was demonstrated on a series of different thin films, such as Copper and Gold, which are typically used in modern circuitry. The healing process relies on the use of a Ni/Al reactive multilayer as a latent heat source. A strongly exothermic reaction taking place in the multilayer is triggered on-demand and the heat wave it generates is harvested to promote a localized weld-repair process at open cracks in the conductive films.

The research is described and now featured on the front cover of external page Advanced Materials Technologies.

Rapid On-Chip Healing of Metal Thin Films, Stefano Danzi,* Volker Schnabel, Johannes Gabl, Alla Sologubenko, Henning Galinski, and Ralph Spolenak, Adv. Mater. Technol. 2018, 1800468, external page DOI:10.1002/admt.201800468