Materials Day 2017 – Materials Today, Tomorrow, and Beyond

Impressions

Impressions

Prof. Nicola Spaldin

Prof. Nicola Spaldin Prof. Markus Niederberger

Prof. Markus Niederberger Prof. Manfred Fiebig

Prof. Manfred Fiebig Prof. Nicolas Spencer

Prof. Nicolas Spencer Prof. Ralph Spolenak

Prof. Ralph Spolenak Prof. Eric Dufresne

Prof. Eric Dufresne Prof. Lucio Isa

Prof. Lucio Isa Prof. Jörg Löffler

Prof. Jörg Löffler Prof. Hans Christian Öttinger

Prof. Hans Christian Öttinger Prof. Laura Heyderman

Prof. Laura Heyderman Prof. Pietro Gambardella

Prof. Pietro Gambardella Prof. André Studart

Prof. André Studart Prof. Jan Vermant

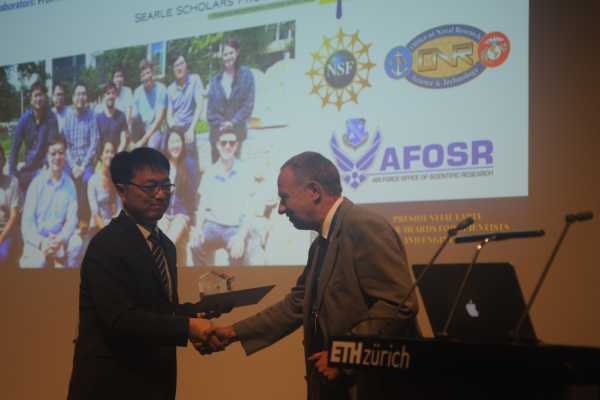

Prof. Jan Vermant Prize Winner Prof. Bozhi Tian, University of Chicago, Prof. Detlef Günther, ETH Vice President Research and Corporate Relations

Prize Winner Prof. Bozhi Tian, University of Chicago, Prof. Detlef Günther, ETH Vice President Research and Corporate Relations Prize Winner Prof. Bozhi Tian, University of Chicago

Prize Winner Prof. Bozhi Tian, University of Chicago Prof. Eric Dufrense, Prize Winner Prof. Bozhi Tian, Prof. Manfred Fiebig

Prof. Eric Dufrense, Prize Winner Prof. Bozhi Tian, Prof. Manfred Fiebig Prof. Ralph Spolenak, Prof. Ludwig Gauckler, Prize Winner Prof. Bozhi Tian, Prof. Nicola Spaldin, Prof. Manfred Fiebig

Prof. Ralph Spolenak, Prof. Ludwig Gauckler, Prize Winner Prof. Bozhi Tian, Prof. Nicola Spaldin, Prof. Manfred Fiebig Thank you for your help: Susanne Blatter, Isabelle Lendvai, Gisela Angst-Schär, Cornelia Aurelio, Patricia Horn, Cristina Pederiva, Claudia Sigel

Thank you for your help: Susanne Blatter, Isabelle Lendvai, Gisela Angst-Schär, Cornelia Aurelio, Patricia Horn, Cristina Pederiva, Claudia Sigel Thank you, Claudia Sigel, for organizing the Materials Day 2017

Thank you, Claudia Sigel, for organizing the Materials Day 2017 Ralph Spolenak thanks Cornelia Aurelio, Gisela Angst-Schär and Claudia Sigel for their help organizing the Materials Day 2017

Ralph Spolenak thanks Cornelia Aurelio, Gisela Angst-Schär and Claudia Sigel for their help organizing the Materials Day 2017 Audience

Audience Audience

Audience Materials Day Banner

Materials Day Banner Flower Decoration

Flower Decoration ETH Main Building

ETH Main Building Lunch Buffet

Lunch Buffet

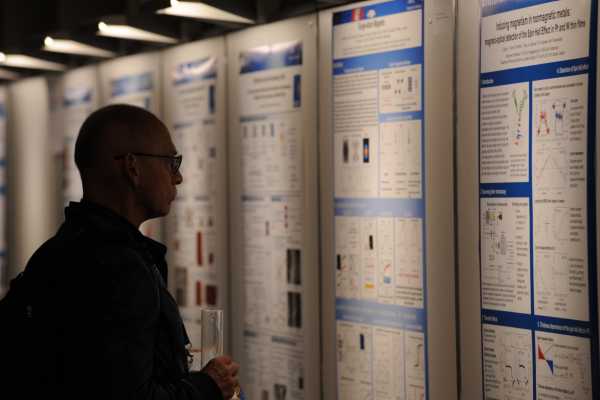

Poster Session

Poster Session Poster Session

Poster Session Poster Session

Poster Session Poster Session

Poster Session Poster Session

Poster Session Poster Session

Poster Session Poster Session

Poster Session At the reception desk

At the reception desk At the reception desk

At the reception desk Reception

Reception Reception

Reception Reception desk, Rina Fichtl, Liz Hoss, Cornelia Aurelio, Gisela Angst-Schär

Reception desk, Rina Fichtl, Liz Hoss, Cornelia Aurelio, Gisela Angst-Schär

A recording of the event is available at the video portal of the ETH

Introduction

Materials Day

Developing materials is essential to addressing the grand technological challenges of the 21st century. Without new materials and processes, advances in areas that we take for granted, ranging from biomedicine to telecommunications, energy storage and manufacturing of complex structures will either not happen or not be sustainable.

Materials Day is an opportunity to get to know the most advanced research directions in the Department of Materials at ETH Zürich in a one-day symposium, which includes talks, a prize award and poster sessions, as well as opportunities for convivial discussions over lunch and coffee.

Department of Materials

The Department of Materials carries out fundamental and applied research in a wide variety of areas of materials science. We investigate different forms of matter, including advanced metal alloys, polymer-metal nanocomposites, complex fluids, soft-condensed biopolymers, functional surfaces, hybrid ceramics and magnetoelectronic materials. Approaches vary from synthesis to experimental studies and processing to theoretical work and large-scale simulation efforts.

The Competence Center for Materials and Processes

The Competence Center for Materials and Processing (MaP) is the multidisciplinary network of ETH Zurich researchers and is dedicated to tackling the grand challenges in Materials and Processes. We promote cross-disciplinary research, education and outreach to industry, academy and society.

Materials Research Prize for Young Investigators

The ETH Materials Research Prize for Young Investigators recognizes outstanding contributions of young investigators that advance materials, from fundamental to applied research. These contributions could include, for example: the discovery of new classes of materials, the observation of novel phenomena leading to either fundamentally new applications and insights, and work that substantially impacts our understanding or applications of existing materials and phenomena. The prize consists of CHF 10,000, a certificate citing the contribution of the recipient, and an allowance for travel to the ETH Materials Day at which the award is presented together with a keynote address by the prizewinner. The Materials Day is a biannual celebration at which the ETH Department of Materials presents its Research to Swiss academia, industry, and the public.

Establishment & Support

The prize is newly established in order to emphasize the fundamental role young researchers play in advancing materials science, spanning fundamental and applied research. It is endowed by the ETH Department of Materials and will be awarded biannually.

Rules & Eligibility

The prize is open to scientists of all nationalities irrespective of where their work has been carried out. Nominations shall be restricted to one per institution. To be eligible for the prize, the researcher should be an assistant professor (or an equivalent form of independent researcher) at the time of nomination.

Nomination & Selection Process

For the nomination, please send the following to the Head of Department, Prof. Ralph Spolenak (ralph.spolenak at mat.ethz.ch):

- A letter of not more than two pages evaluating the qualifications of the nominee.

- A biographical sketch, including publication list.

- A list of the up to five most important publications.

- Two seconding letters by individuals not connected to the nominee through advising relationships.

The selection will be conducted by three tenured professors of the Department of Materials and the Head of Department.

Prize Winner

Prof. Bozhi Tian, University of Chicago, 2017

He pioneered new chemical reactivity in inorganic nanowires to gain control of their morphology and make them biocompatible. This work has enabled new bioelectric measurements within cells.

Program

Speaker & Abstracts

Prof. Nicola Spaldin

Head of Materials Theory

Looking Beyond the Silicon Age

Every advance in human civilization, starting from the Stone Age through the Iron Age to the Silicon Age of today, has been driven by a development in materials. On a smaller time-scale, the ever-increasing standards of living that we are enjoying during our Silicon Age are enabled by ongoing improvements in the quality of the silicon material that forms the core of our microelectronic devices. But we face a crisis: Worldwide use of microelectronics is expanding so rapidly, that by many projections, silicon-based devices will consume half of our global energy supply within a few decades. And this is not sustainable.

I will describe new materials that we are developing in the Materials Department at ETH to circumvent this energy bottleneck in human progress, and to answer the question “What lies beyond the silicon age?”

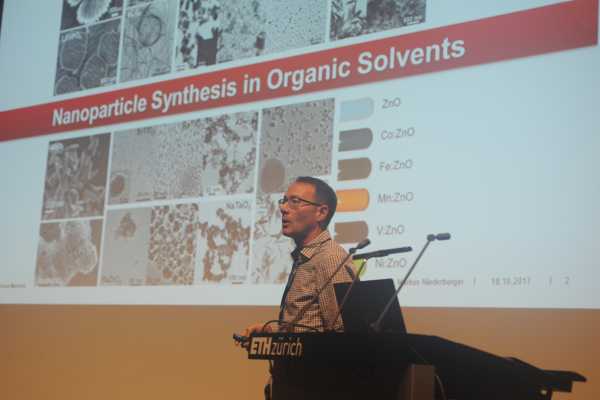

Prof. Markus Niederberger

Head of Laboratory for Multifunctional Materials

Nanoparticle-Based Aerogels: New Materials for Energy Storage and Conversion

Aerogels with their low densities, high porosities and large surface areas are unique and fascinating materials. Traditionally, they are synthesized by molecular routes based on aqueous sol-gel chemistry. In the last few years, the assembly of preformed nanoparticles as building blocks became a viable alternative to improve the crystallinity and to expand the structural, morphological and compositional complexity of aerogels. Unfortunately, the high brittleness strongly limits their use in the form of monoliths.

To solve this problem, the Laboratory for Multifunctional Materials pursues two strategies: Improvement of the mechanical properties by preparing composite aerogels and development of a flow reactor, which enables the use of aerogel samples in gas phase reactions under full preservation of the monolithic structure.

The talk will present two illustrative examples for both strategies. Composite aerogels prepared from graphene oxide and molybdenum sulfide are structurally flexible and can be used as anode materials in lithium and sodium ion batteries. Aerogels composed of gold and titania nanoparticles are translucent and fragile, but can directly be studied as monoliths in a home-made flow reactor for photocatalytic CO2 reduction.

Prof. Manfred Fiebig

Head of Laboratory for Multifunctional Ferroic Materials

Shining Light on Oxide Electronics

Oxides can now be grown with an accuracy matching those of semiconductors. At the same time, they possess inherent functionalities that semiconductors can never develop, like long-range magnetic or electric order, superconductivity, “colossal” magnetoresistance and a profound oxygen chemistry. In our lab, we possess the tools to manufacture oxide heterostructures with atomic precision and well-tailored magnetoelectric properties, supported by advanced characterization and simulation tools. In particular, we apply laser-optical techniques for both probing and manipulating the multifunctional ferroic state. Rigorous consolidation of light-matter interaction and oxide electronics could become the key for leaving the semiconductor age behind.

Prof. Nicholas Spencer

Head of Surface Science and Technology

Imitating Cartilage with Polymers

Cartilage represents an exquisite, natural tribological structure. It can withstand substantial loads (e.g. in our knees after Christmas), ensures low friction and negligible wear for decades, and does this without a blood supply! We don’t yet know all the subtle secrets of cartilage, but those we know, we would like to imitate with synthetic polymers.

The short-term goal is that we will come up with new, highly lubricious materials that could have industrial applications. The long-term hope is that we will enable the fabrication of materials that can be implanted, to replace cartilage in knees and hips that has been damaged by injury or disease.

Prof. Ralph Spolenak

Head of Laboratory for Nanometallurgy

Self Organisation on the Nanoscale – A Pathway to Large Area Applications

In the past decade many advances in both mechanical as well as optical metamaterials have been made with feature sizes approaching the length scale of tens of nanometers. Most of these materials have been created by advanced lithography techniques making it too expensive in terms of cost and time to scale them up to industrially relevant areas. This contribution focuses on self organization to form nanostructures to enhance mechanical, electrical and optical properties with applications ranging from wear resistant coatings over arc resistant materials to epsilon-near-zero materials. The dominant principles of phase separation will be demonstrated on systems such as Ta-Cu, W-Cu, W-Mg, W-Al, Cu-Al, Ni-Au and Ag-Ge.

Prof. Eric Dufresne

Head of Soft and Living Materials

Surface Stresses and Self-Assembly in Soft Solid Composites

The properties of materials are usually determined by the properties of molecules in the bulk. However, soft solids can be so weakly connected that their surface properties play a central role. I will describe two examples of the interplay of surface and bulk elastic stresses in soft solid composites. In the first, surface forces dominate the mechanical response of a solid composite. In the second, the competition of bulk and elastic forces drives the self-assembly of composite materials with a well-defined length scale.

Prof. Lucio Isa

Head of Interfaces, Soft Matter and Assembly

Active Colloids: Breaking the Symmetry to Introduce Propulsion

Breaking symmetry is at the very core of achieving propulsion at the microscale, and nature has perfected a range of different strategies to reach this goal for swimming microorganisms. Scientist continue to take inspiration from these examples to produce artificial micro-swimmers. A common way to achieve propulsion at the colloidal scale is to produce artificial particles that have asymmetric shapes and surface properties. We developed a new fabrication strategy to create micro-swimmers with full control on their geometrical and compositional asymmetry. The method is based on the sequential deposition of microspheres on topographical templates, where we independently define the swimmers’ shape by defining the shape of template, and we program their composition by fixing the deposition sequence. I will show how we can use this fabrication strategy to design and obtain particles that translate, rotate, switch between these two modes of motion and even perform drag-and-drop tasks in crowded environments, propelled by uniform AC electric fields. These results show how the design of micro-swimmers can enable the development of active components for the realization of autonomous miniaturized machines working in complex environments.

Prof. Jörg F. Löffler

Head of Metal Physics and Technology

Correlated Atomic-Scale Analysis Drives the Future of Materials Development

The development of new materials and the understanding of their microstructure-property relations often rely on studies where atomic resolution can be achieved. Apart from atom-probe tomography, such resolution is nowadays also obtained by transmission electron microscopy thanks to the advent of spherical aberration corrections coupled to large-angle X-ray detectors. New MEMS-based experimental capabilities also allow for atomic-scale in situ investigations in dependence of temperature, chemistry, etc. We will illustrate how a basic understanding of the structure and dynamics on the atomic scale via correlated microscopy and tomography can drive the future of materials development. Examples will be given primarily from the metals area, involving metastable phase formation for new materials creation, detailed understanding of age-hardening in light metals, improvement of magnetic systems, and the generation of new biomaterials.

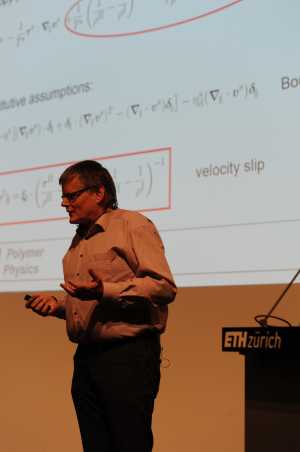

Prof. Hans Christian Öttinger

Head of Polymer Physics

Do Interfacial Material Properties Exist?

Considering coexisting phases, say a liquid and its vapor, one can ask the following questions: Can the temperature of an interface be different from the temperatures of the adjacent bulk phases, even if they are less than a nanometer away? Can the interface possess a viscosity that is independent of the properties of the surrounding bulk fluids? Conceptual clarifications are of obvious importance for guiding both modeling efforts and experiments at interfaces.

Prof. Laura Heyderman

Head of Mesoscopic Systems

The Magic of Mesoscopic Magnets

Reducing a magnet’s size to below a micrometre can result in surprising behaviour. For example, a magnet has a north and a south pole and, if you cut it in half, you get two magnets, each with its own north and south pole. However, in artificial spin systems made from nanoscale magnets arranged on various lattices, it is possible to separate the poles using a magnetic field, and let them travel through the system along a one-dimensional path. This and other curious phenomena involving mesoscopic magnets will be presented. Such effects are not only of fundamental interest, but can be harnessed for a wide variety of applications, including data storage and transfer, communications, sensors and actuators.

Prof. Pietro Gambardella

Head of Magnetism and Interface Physics

The Art of Magnetic Writing

Modern computing technology is based on our ability to write, store, and retrieve digital information as efficiently as possible. Magnetic bits miniaturized to less than a millionth part of a human hair allow us to store Terabytes of digital information for a period of years. The state of a magnetic bit, however, is still controlled by means of magnetic fields produced by wires and coils, a 200-year old methodology that has severe limitations in scalability and energy efficiency. In this talk, I will describe a paradigmatic change in magnetic switching, which emerges in materials with strong spin-orbit interaction. Our findings have applications in ultrafast magnetic random access memories with high endurance.

Prof. André Studart

Head of Complex Materials

3D Printing of Biologically-Inspired Composites

Composite materials in nature exhibit heterogeneous architectures that are tuned to fulfill the functional demands of the surrounding environment. Examples range from the cellulose-based organic structure of plants to highly mineralized collagen-based skeletal parts like bone and teeth. Because they are often utilized to combine opposing properties such as strength and low-density or stiffness and wear resistance, the heterogeneous architecture of natural materials can potentially address several of the technical limitations of artificial homogeneous composites. However, current man-made manufacturing technologies do not allow for the level of composition and structural control found in natural heterogeneous systems. In this talk, I will show that 3D Printing offers a new exciting pathway for the fabrication of biologically-inspired composite materials with unprecedented heterogeneous architectures and functionalities.

Prof. Jan Vermant

Head of Soft Materials

Engineering Soft Materials: Interfacial Design

Foams, emulsions, polymer-polymer systems as well as biological cells all rely on the presence of a stabilising interface. In this talk we will discuss the advances made to study and describe the mechanical and rheological properties of such interfaces and how novel processing techniques enable us to generate materials with designer interfaces. Such materials have applications from classical materials science, over food and biomedical technology to the field of materials for energy. We will give a few examples of hopefully eye-catching applications.

Poster Session

Core Research Area 1

Soft Matter

Soft and Living Materials

Prof. Dr. Eric Dufresne

- Reversible Adhesion of Particles on Lipid Bilayers through Electrostatics or Depletion

H. Spanke and C. Francois-Martin - Direct Measurement of Surface Stress of Stretched Soft Solids

R. Style - Surface Stress and Adhesion of Hydrogels

K. Smith-Mannschott

Interfaces, Soft Matter and Assembly

Prof. Lucio Isa

- Wetting of Rough Particles at Flat Liquid-Liquid Interfaces

M. Zanini, S.E Anachkov, C. Marschelke, E. Marini, A. Synytska , L. Isa - Programmable assembly of hybrid colloidal microswimmers

S. Ni, M. A. Fernandez Rodriguez, J. Leemann, E. Marini, I. Buttinoni, L. Isa, H. Wolf

- Janus microswimmers at oil-water interfaces

K. Dietrich, D. Renggli, M. Zanini, G. Volpe, I. Buttinoni, L. Isa

Polymer Physics

Prof. Dr. Hans Christian Öttinger

- Coarse-graining via large-deviation theory

A. Montefusco, H. Ch. Öttinger, M. A. Peletier - Coarse Graining of Nonionic Surfactants adsorbed at Fluid-Fluid Interfaces

A. Moghimikheirabadi, H. Ch. Öttinger, L. M. C. Sagis, P. Ilg

Surface Science and Technology

Prof. Nicolas Spencer

- Smart Surfaces orHow to Reversibly Switch Enzymatic Activity on Polymer Brushes with Light

M. Dübner, V.J. Cadarso, T.N. Gevrek, A. Sanyal, N.D. Spencer, C. Padeste - Probing soft matter via a 2-step indentation method

R. Simic, Ch. H. Mathis, Y. Gombert, N. D. Spencer - Hairy and lubricious copolymers for restoring cartilage surface properties

G. Morgese, M. Zenobi-Wong, E. M. Benetti - It’s All About Topology: Evolution of Polymer Brushes and Their Performance

M. Divandari, L. Trachsel, G. Morgese, W. Yan, S. N. Ramakrishna, E. M. Benetti

Soft Materials

Prof. Dr. Jan Vermant

- Complex fluid-fluid interfaces and their role in emulsion and foam stability

A. Alicke, P. Beltramo, E. Chatzigiannakis, F. Erni, S. Geisel, J. Vermant - Physical Exercises with Polymers: Stretching

A. Brem, G. Ghazaryan, J. Vermant and Th. A. Tervoort - The fast and the furious 9: drifting at high shear and high frequency

G. Colombe, B. Schroyen, J. Vermant - Large model biomembranes – a new setup to study membrane function

L. Scheidegger, P. Beltramo, J. Vermant

Core Research Area 2

Magnetoelectronic Materials

Multifunctional Ferroic Materials

Prof. Dr. Manfred Fiebig

- Probing ferroic order in thin film heterostructures

G. De Luca, N. Bonačić, J. Nordlander, M. Fiebig, M. Trassin - Optically induced dynamics in strongly correlated materials

Ch. Tzschaschel, S. Pal, Th. Lottermoser, M. Fiebig - (Multi-)ferroic order and domains by SHG

M. Giraldo, A. Bortis, E. Hassanpour, M. Weber, Th. Lottermoser, M. Fiebig - Properties of domain topologies revealed by SPM

J. Lehmann, J. Schaab, P. Schönherr, M. Fiebig

Magnetism and Interface Physics

Prof. Pietro Gambardella

- Sub-ns magnetization switching induced by current injection in ultrathin Pt/Co/AlOx dots

M. Baumgartner, K. Garello, J. Mendil, C. O. Avci, E. Grimaldi, C. Murer, J. Feng, C. Stamm, M. Gabureac, Y. Acremann, S. Finizio, S. Wintz, J. Raabe, and P. Gambardella - Inducing magnetism in nonmagnetic metals: magneto-optical detection of the Spin Hall Effect in Pt and W Thin Films

C. Stamm, C. Murer, M. Berritta, J. Feng, M. Gabureac, P. M. Oppeneer, and P. Gambardella, - A diamond quantum sensor for nanoscale magnetic imaging

M. S. Wörnle, P. Welter, M. Palm, K. Chang, L. Lorenzelli, P. Dao, J. Rhensius, C. L. Degen and P. Gambardella - Single-Atom Magnets

L. Persichetti, F. Donati, S. Rusponi, S. Stepanow, C. Wackerlin, A. Singha, R. Baltic, K. Diller, E. Fernandes, F. Patthey, J. Dreiser, Z. Sljivancanin, K. Kummer, C.Nistor, H. Brune and P. Gambardella

Mesoscopic Systems

Prof. Dr. Laura Heyderman

- Artificial spin systems

H. Arava, O. Sendetskyi, D. Schildknecht, N. Leo, P. Derlet, A. Kleibert, H. Luetkens, S. Holenstein, S. Lee, G. Möller - 3D magnetic systems and their characterisation

C. Donnelly, M. Guizar-Sicairos, V. Scagnoli, S. Gliga, M. Holler, J. Raabe, L. Heyderman - Ultrafast dynamics in mesoscopic systems

N. Gurung, S. Saha, T. P. Dao, E. Kirk, P. Gambardella, V. Scagnoli and L. Heyderman - Magneto mechanical materials

P. Testa, J. Cui, A. Weber, R. Style, P. Derlet, E. Dufresne and L. Heyderman

Materials Theory

Prof. Nicola Spaldin

- Magnetic, Electric and Multiferroic Order

A. Edström, N. Fedorova, Ch. Gattinoni and A. Narayan - Beyond Conventional Order

W. Tarantino, Q. Meier, M. Taherinejad - Dynamical Mean Field Theory for Strongly Correlated Oxides

A. Hampel, S. Beck, J. Souto Caseras

Core Research Area 3

Hybrid Materials and Interfaces

Multifunctional Materials

Prof. Markus Niederberger

- Structure-dependent Luminescence in HfO2 Nanocrystals: Towards Rare-Earth-free White Light Emitting Phosphors

I. Villa, A. Vedda, M. Fasoli, R. Lorenzi, N. Kränzlin, F. Rechberger, G. Ilari, D. Primc, B. Hattendorf, M. Niederberger, A. Lauria - Homoconjugation in Poly(Phenylene Methylene)

A. Braendle, A. Perevedentsev, N. J. Cheetham, P. N. Stavrinou, J. A. Schachner, N. C. Mösch-Zanetti, M. Niederberger, W. R. Caseri - Battery engineering: from nano-/micro-structure design to material printing & packaging for flexible batteries

X. Chen, E. Tervoort-Gorokhova, F. G. B. Ooms, Y. Xu, Y. Xiao, M. Niederberger

Complex Materials

Prof. Dr. André Studart

- The role of mineral interconnectivity in nacre-like composites

M. Grossman, F. Bouville, K. Masania, R. Libanori, A. R. Studart - Microcapsules with hard-soft bilayer shells made by bulk emulsification

E. Jeoffroy, A. F. Demirörs, P. Schwendimann, S. dos Santos, S. Danzi, A. Hauser, M. N. Partl, A. R. Studar - Geologically-inspired strong bulk ceramics made with water at room temperature

F. Bouville, M. Haug, A. R. Studart - Functional materials made by microfluidic multichannel step emulsification

A. Ofner, D. G. Moore, P. A. Rühs, P. Schwendimann, M. Eggersdorfer, E. Amstad, D. A. Weitz, A. R. Studart

Core Research Area 4

Metallic Materials

Metal Physics and Technology

Prof. Dr. Jörg Löffler

- Localized cooling rates and shear banding in bulk metallic glasses

F. Haag, G. Kurtuldu, K. F. Shamlaye, S. Jekal, P. Thurnheer, J. F. Löffler - Thermophysical properties at ultrafast rates

G. Kurtuldu, K. F. Shamlaye, F. Haag, J. F. Löffler - Biodegradable Mg–Zn–Ca-lean alloys for temporary implant applications

M. Cihova, L. Berger, N. Schai, R. Schäublin, P. J. Uggowitzer, J. F. Löffler - Magnetic metallic nanostructures

L. Pierobon, D. Koulialias, A. Hagmann, L. Koch, R. Schäublin, M. Charilaou, J. F. Löffler

Nanometallurgy

Prof. Dr. Ralph Spolenak

- From reactive multilayers to self-healing metallic systems

S. Danzi, V. Schnabel, A. Soligubenko, R. Spolenak - Between Hard and Tough – materials design for laser cladding

J. Engel, F. Wirth, R. Spolenak - Portevin-Le Chatelier Effect in Al-Cu at Small Scales

Y. Xiao, R. Spolenak, J. M. Wheeler - Plasticity and Size Effects in Germanium: from Cryogenic to Elevated Temperatures

M. Chen, R. Spolenak, J. M. Wheeler